ROBOT SORTING SYSTEM

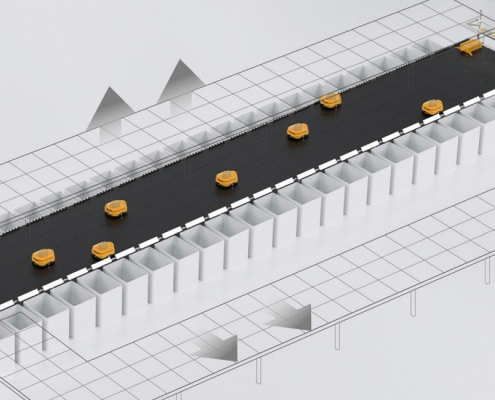

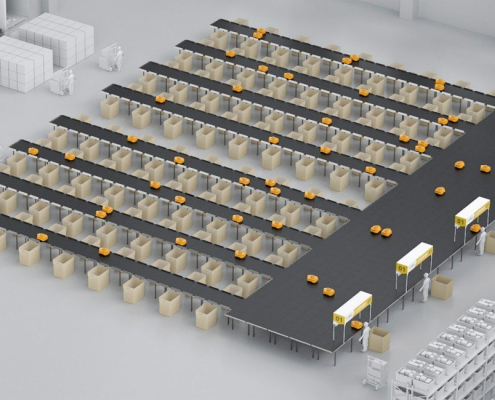

LIBIAO sorting system is designed to move autonomously through a warehouse or distribution center, sorting and organizing packages or products. The system use a combination of robots, sensors, cameras, and software to identify and sort items based on their barcode.

Mobile sorting robots can be used to streamline the sorting and distribution process, reducing the need for manual labor and improving the efficiency and accuracy of the operation. Some of the advantages of using mobile sorting robots include:

• Increased Efficiency: Mobile sorting robots can work 24/7 and can sort packages at a faster rate than human workers

• Improved Accuracy: Sorting system accuracy can reach 99.99%

• Scalability: can be added or removed from a fleet as needed to match changes in production volume

• Enhanced Safety: By automating the sorting process, mobile sorting robots can help reduce the risk of accidents or injuries in the workplace

• Cost Savings: Mobile sorting robots can help reduce labor costs over time, as they require minimal human intervention and can operate at a lower cost per package

• Rapid deployment: take 4-8 weeks to deploy

• Space utility: than half with other system, effectively saving cost on space.

• Easy maintenance

Below are some typical platform, also we can customize base on customer requirement:

RCS Robot Dispatching Control System

- Integrated and intelligent system

- The system integrates a human-computer interaction (HCI) interface, path planning, robot communication, barcode/QR code scanner communication, external data communication, charging, lifter and other modules to achieve integrated, intelligent, automatic operations and maintenance.

- Efficient dispatching of robot clusters

- The system can simultaneously dispatch hundreds or thousands of sorting robots to work together, including different types of robots, and can plan the optimal path for each robot to improve the stability of robot operations and the efficiency of sorting.

- Significantly increased production capacity

- Compared with systems using conventional Wi-Fi communication, our self-designed dispatch system, combined with a self-innovated wireless communication system, has achieved a significant increase in production capacity.

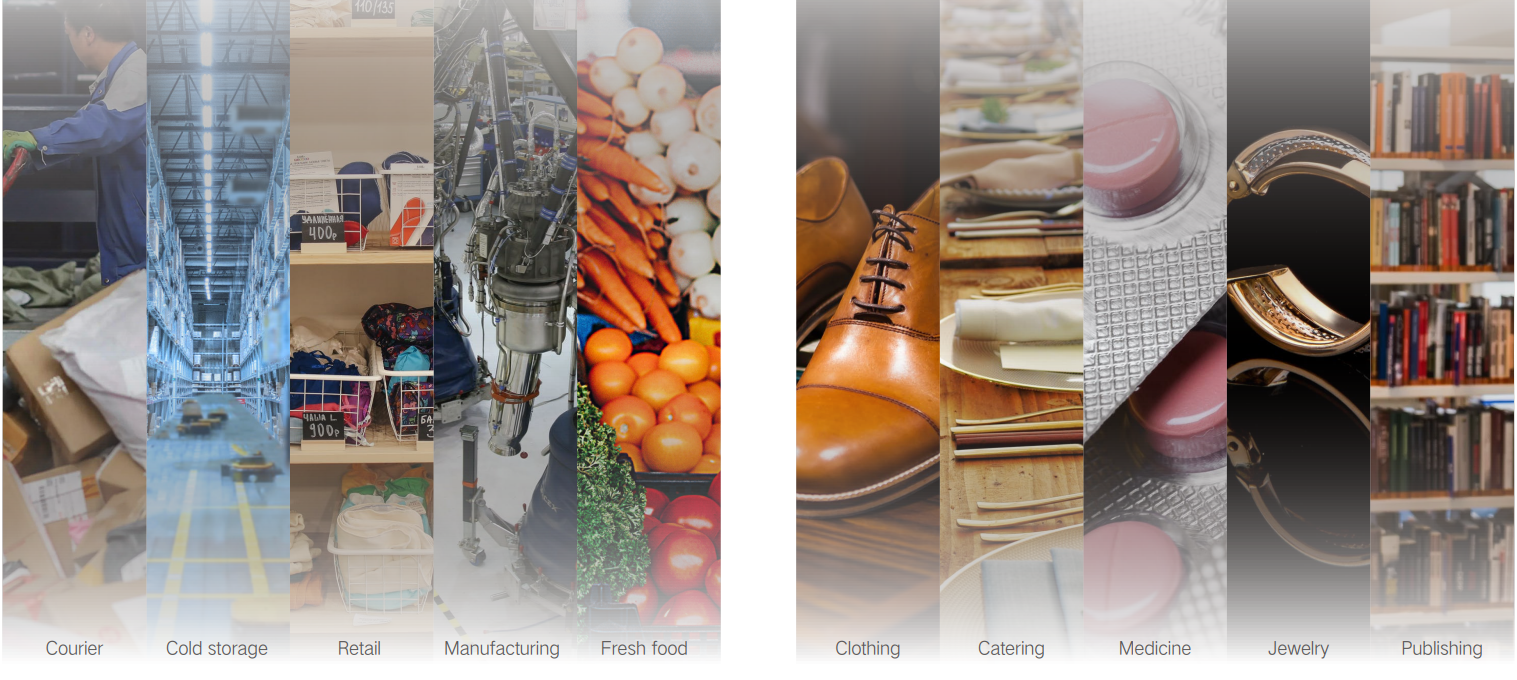

Due to many advantages, sorting system can be applied in different industries and scenarios: courier, cold storage, retail, manufacturing, fresh food, clothing, catering, medicine, jewelry, publishing