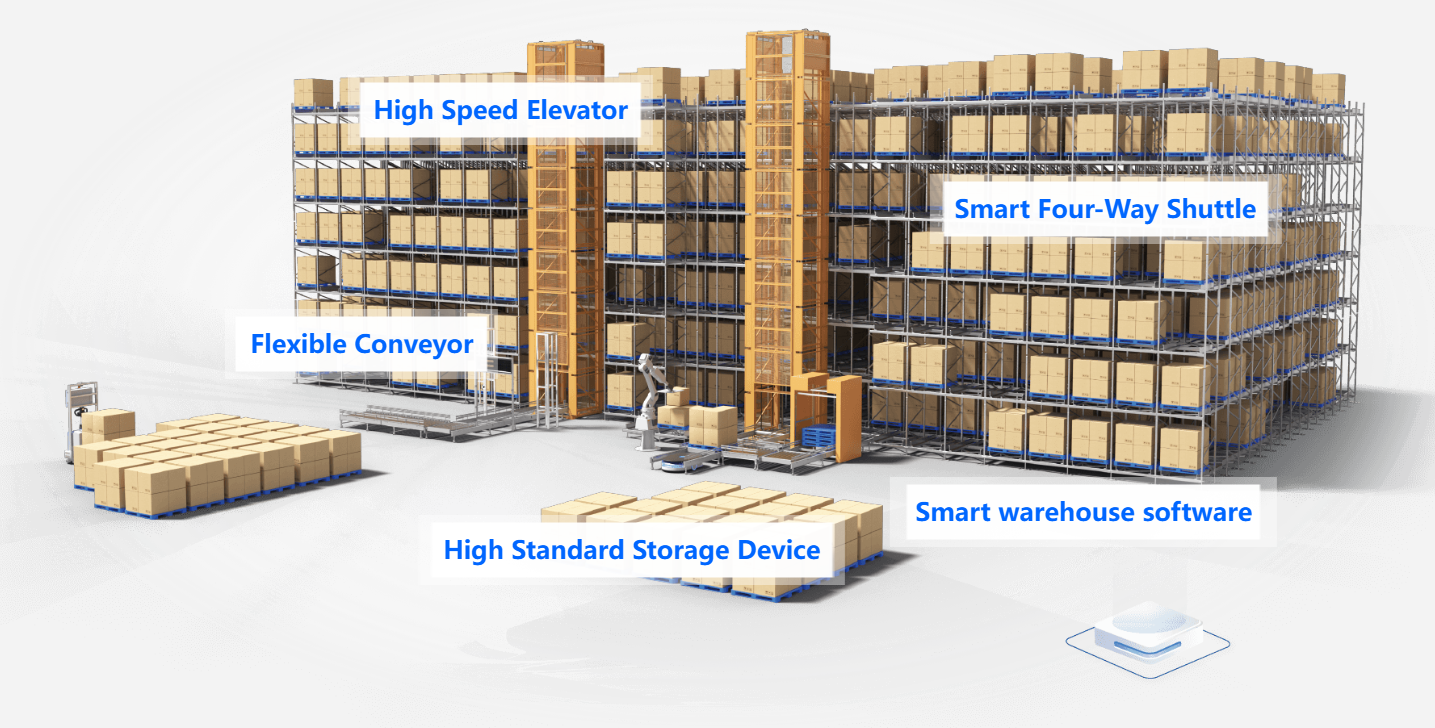

FLASH SHUTTLE PALLET EFFICIENT STORAGE SYSTEM

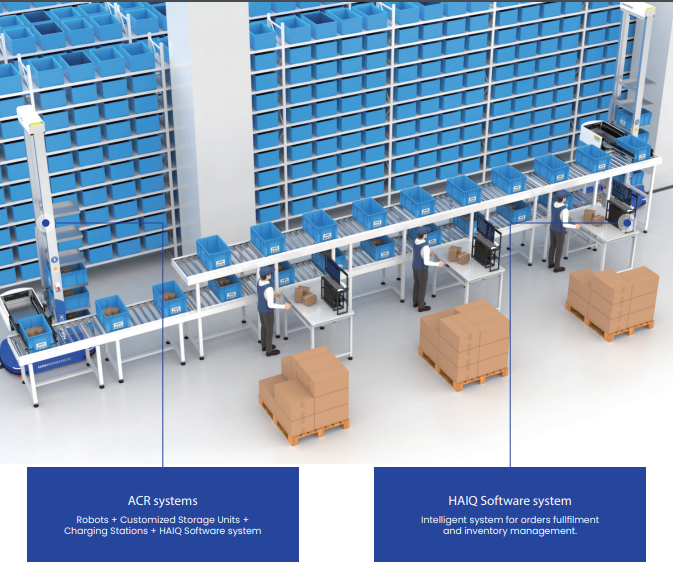

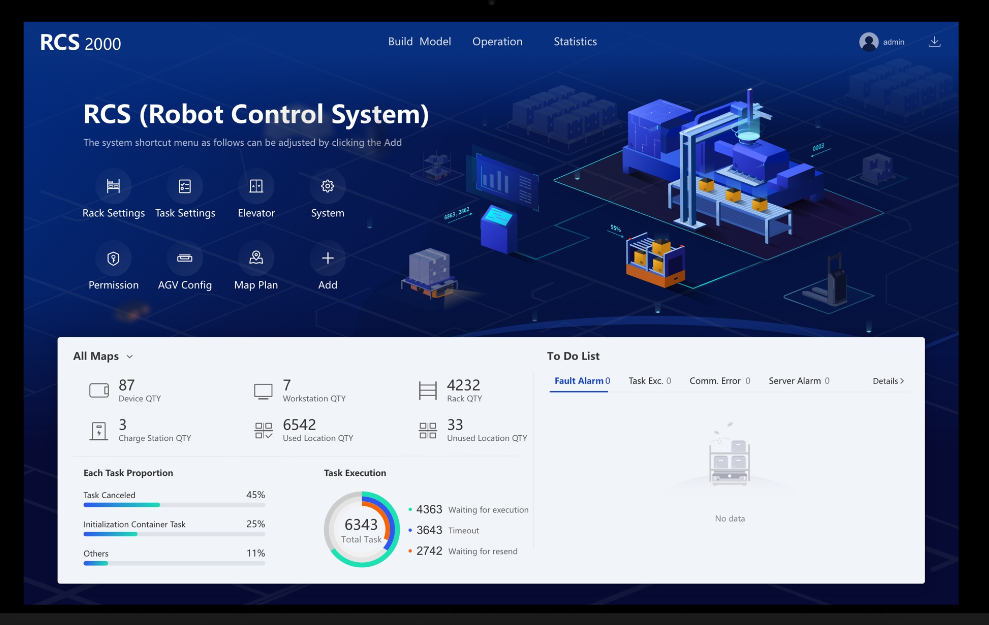

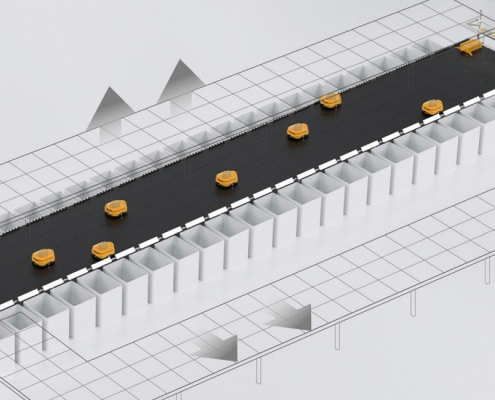

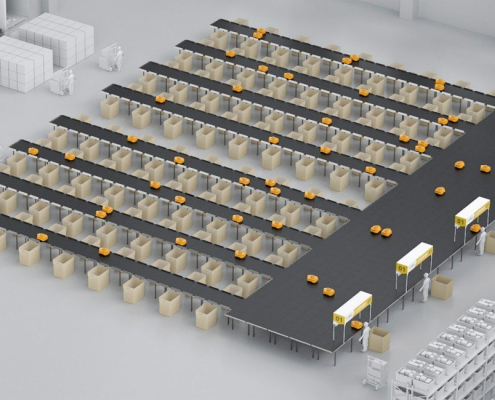

The solution of Flash shuttle Pallet Efficient Storage System covers smart four-way shuttle, high-speed elevator, flexible conveyor line, high-standard racks and pallets and smart storage software (IWMS, IWCS, RMS). According to the characteristics of warehouses and customer needs, we provide customers with high-efficiency, high-density, high-flexibility, fast delivery, and high performance/price ratio “pallet-to-person” solutions.

Some of the advantages of using smart four-way shuttle include:

- – Ultra-fast operation efficiency: The overall operating efficiency is 2-3 times that of traditional warehouses

- – Ultra-high storage density: The storage density is 4-6 times that of traditional storage solutions

- – Flexible adaptation to various scenarios: Can be used in more than 90% of pallet storage scenarios

- – Flexibility to adapt to business needs: Flexible response to space constraints and changes in business stages

- – 2-3 months high quality delivery: 100% high-quality delivery, ensuring no unfinished projects

- – Quick ROI: Reduce labor input by 50%-80%, and quickly return on investment

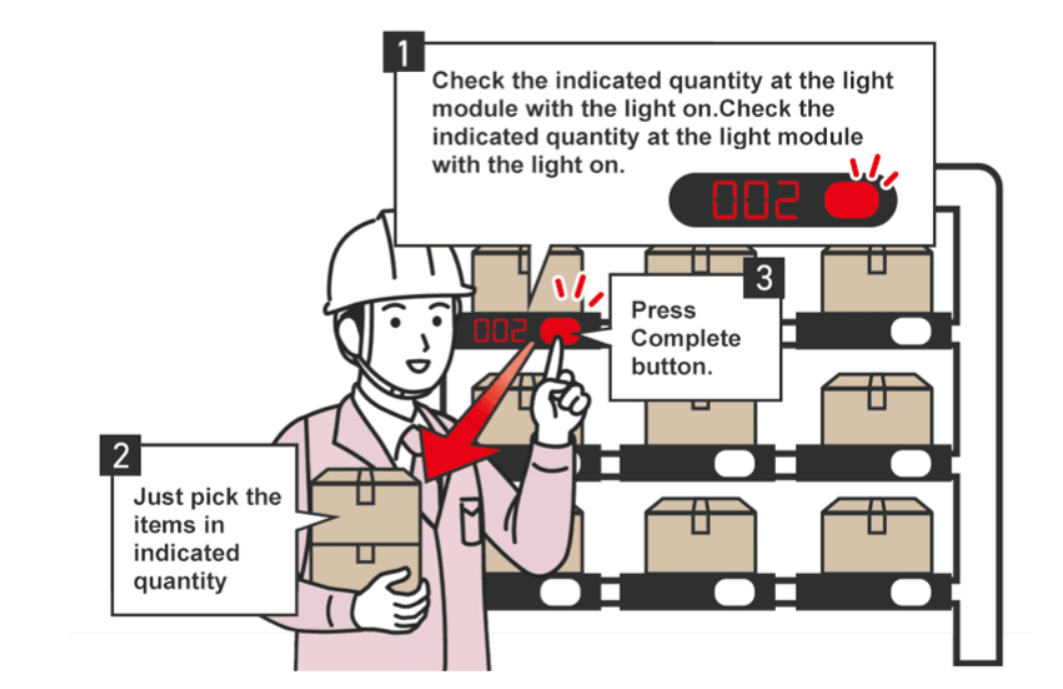

- Smart four-way shuttle applied in customer site: