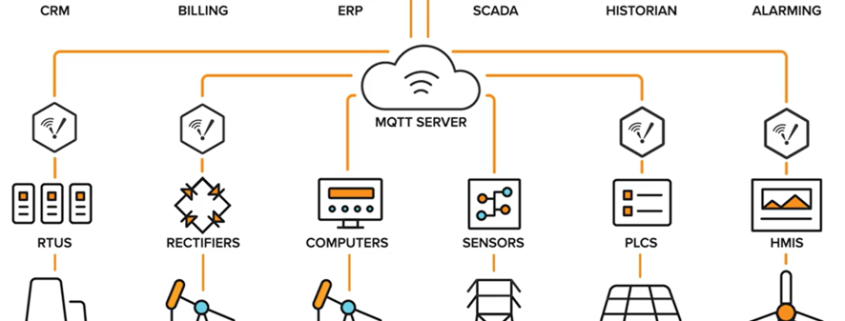

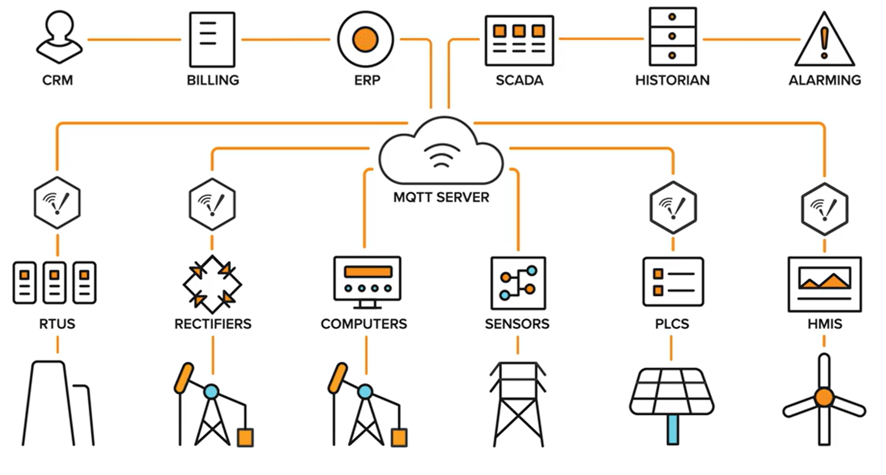

INDUSTRIAL INTERNET OF THINGS – IIOT

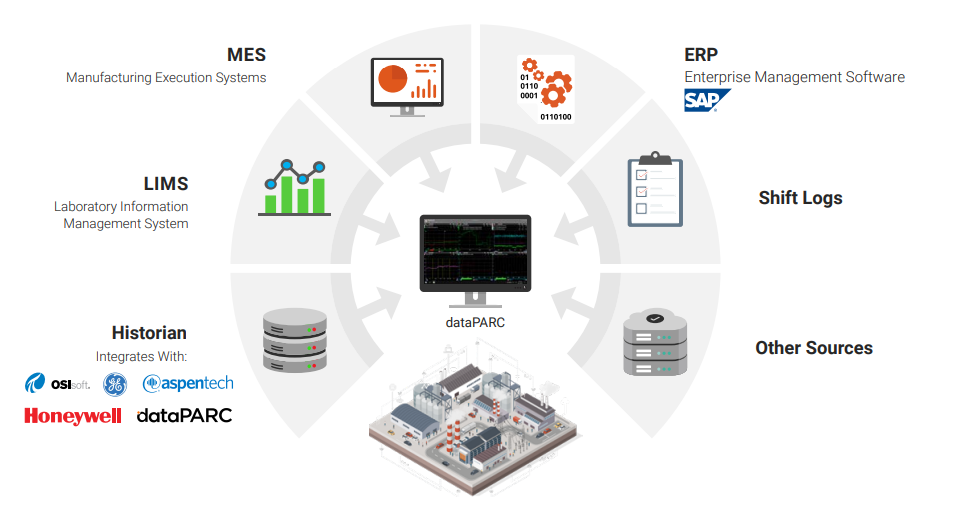

Industrial Internet of Things represents the integration of physical machinery, sensors, and devices with the digital world. IIoT enables these assets to communicate, collect data, and make informed decisions autonomously for industries such as manufacturing, energy, agriculture, transportation, .. by embedding sensors, actuators, and communication technologies into industrial assets.

The IIoT offers a multitude of benefits that have the potential to revolutionize industries and reshape the way businesses operate. Here are some key advantages of adopting IIoT solutions:

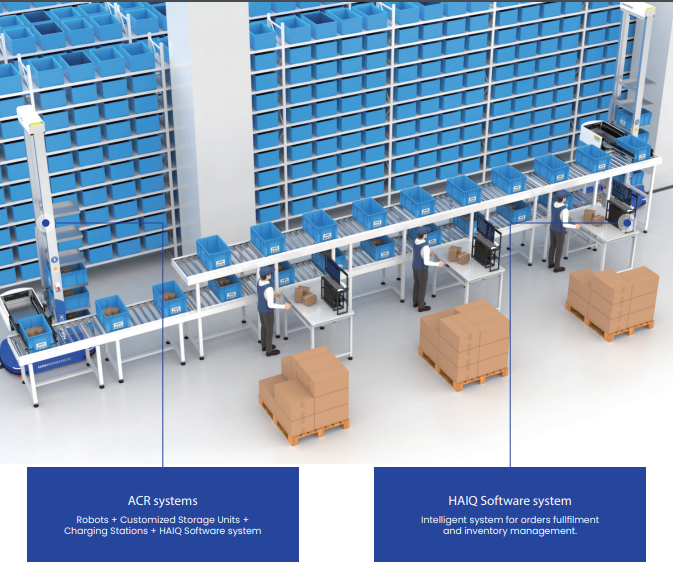

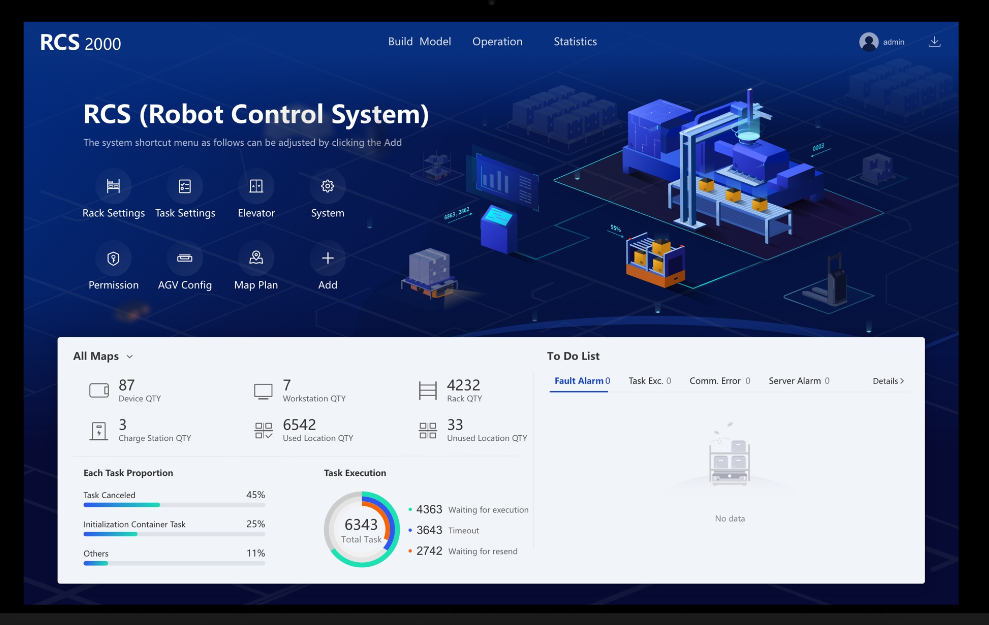

- Operational Efficiency and Productivity Enhancement: IIoT enables real-time monitoring of equipment and processes, allowing businesses to optimize operations, predict maintenance and make data-driven decisions, this leads to streamlined workflows, reduced downtime, and increased overall productivity.

- Cost Reduction: Through improved asset management & predictive maintenance so company can reduce maintenance costs, and enable better control and optimization of energy usage through sensors and data analytics

- Enhanced Quality Control by allowing continuous monitoring and data collection during production processes. This enables real-time quality control checks, identifying defects or variations early in the process and ensuring products meet high standards.

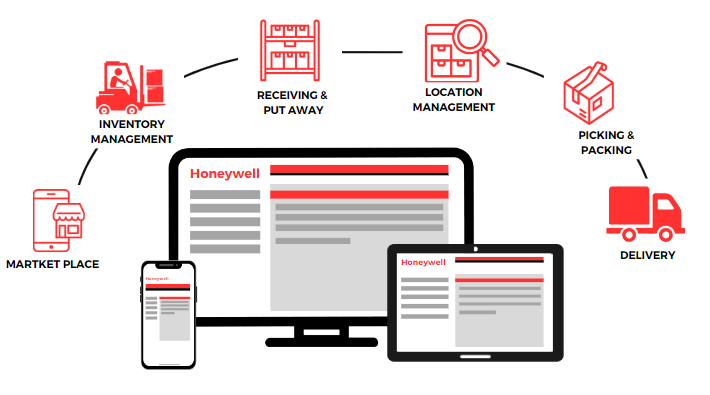

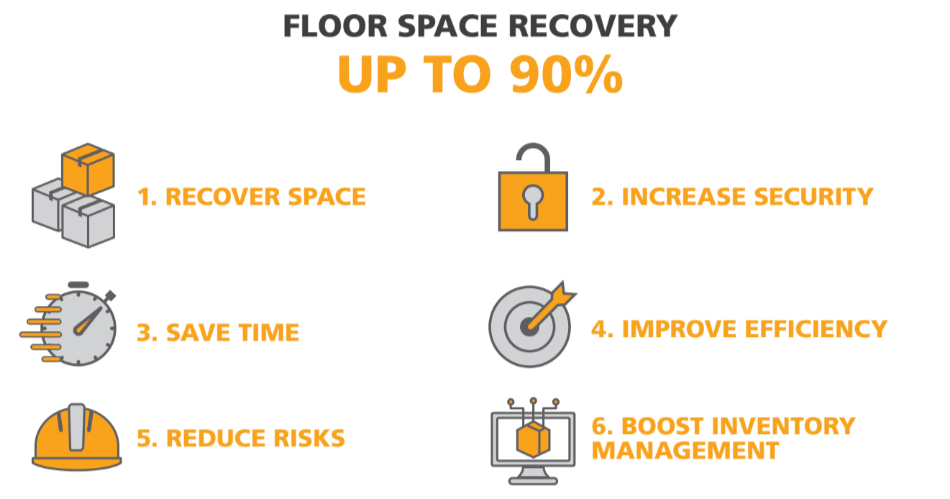

- Inventory Management: by real-time tracking inventory levels and movements. This helps prevent out of stock, reduce excess inventory, and optimize supply chain management.

- Remote Monitoring and Control: allows remote monitoring of operations, enabling businesses to manage and control equipment and processes from anywhere even if in meeting or business trip.

- Enhance safety work place: sensors can monitor workplace environments for hazardous conditions, such as temperature extremes, gas leaks, or toxic fumes, helps ensure the safety of workers and compliance with safety regulations.